The Soprafix HP underlayment, with integrated separating membrane, was mechanically fixed. In this way, the existing PVC in the surface can be preserved. A top layer of Sopralene Optima was then installed.

The PVC roofing on the upstands was removed and a double layer of Sopralene Optima was placed under the air conditioners as additional protection.

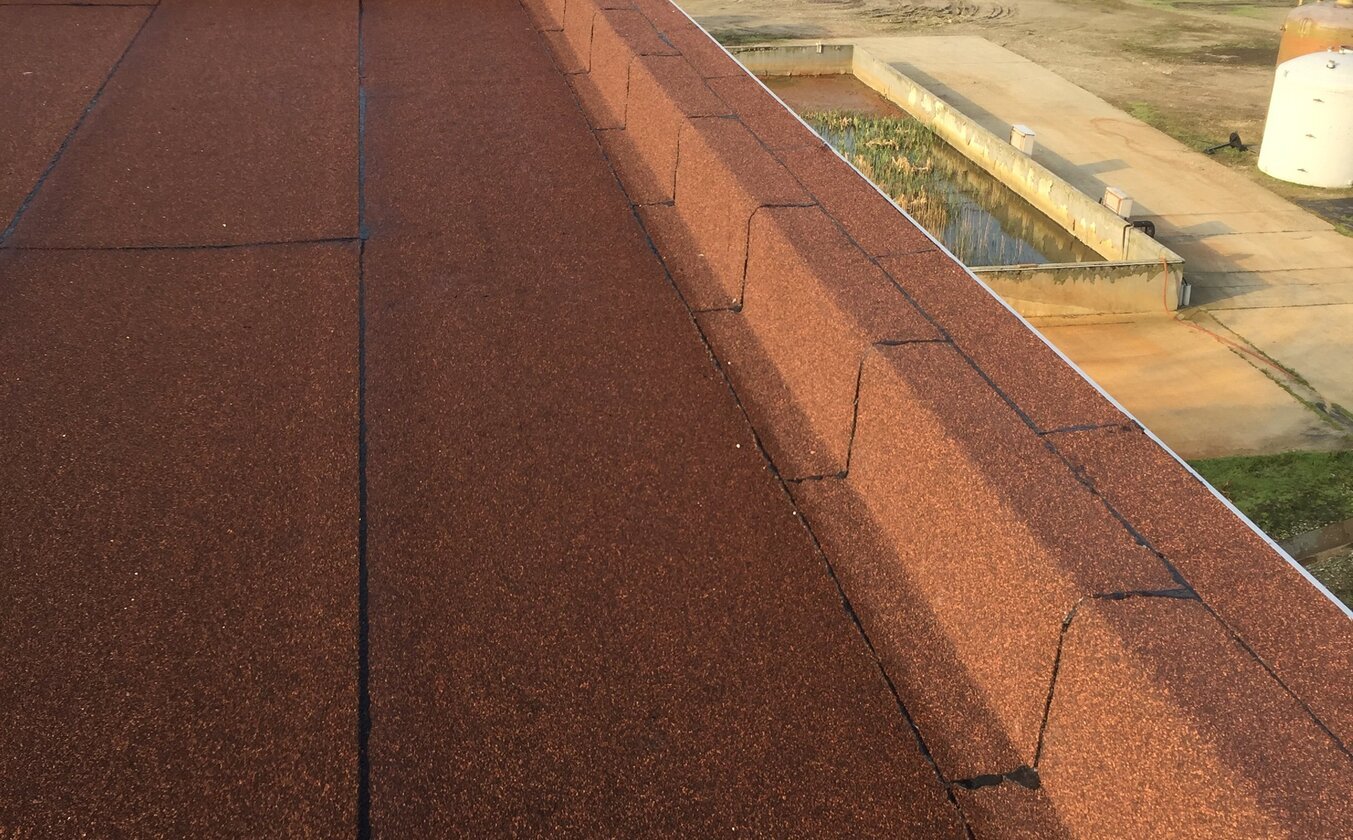

After installing the roofing with Sopralene Techno, roof edge profiles were again provided at the upstands. When connected to higher walls, a wall connection profile is installed to ensure waterproofness. These were also sealed elastically afterwards. Renewal of all edge trims was also provided.

Lead-throughs are finished with a liquid waterproofing system, Alsan Flashing. A small canopy over the cable lead-throughs was also provided.

The two cracks in the masonry were repaired by means of the helifix system. Slots were cut in the cracked joints into which stainless steel rods were placed in a shrinkage-free mortar. In this way, the cracks were repaired, and the structure strengthened.